The LC-α is the best-selling hybrid laser machine, with over 3000 units operating worldwide since its introduction in 1993, proving its reliability.

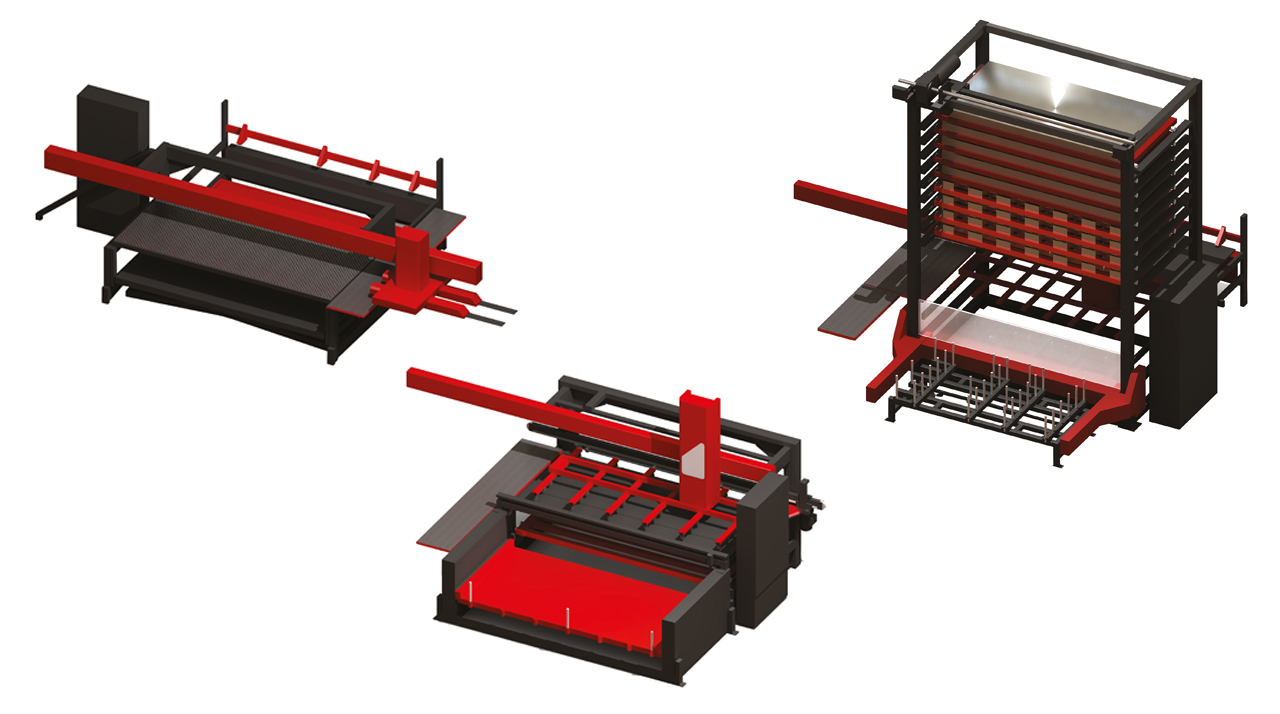

The new LC-αV NT range makes sheet metal loading extremely easy, a feature characteristic of the table type. Many of the new machine characteristics are based on our response to listening to customers' needs. The result is an updated range of laser machines that can cut greater thicknesses at higher speeds, with more accuracy and ease of use. The LC-αV is also ideal for automation applications.

HIGH SPEED AND QUALITY:

The new, 3.5 kW CO₂ oscillator developed by AMADA offers a greater density beam, for the processing of thin to medium parts.

PERFECT INTEGRATION WITH AUTOMATION SYSTEMS:

Thanks to its hybrid structure, the LC-ALPHA is ideal for automated applications, allowing round-the-clock processing.

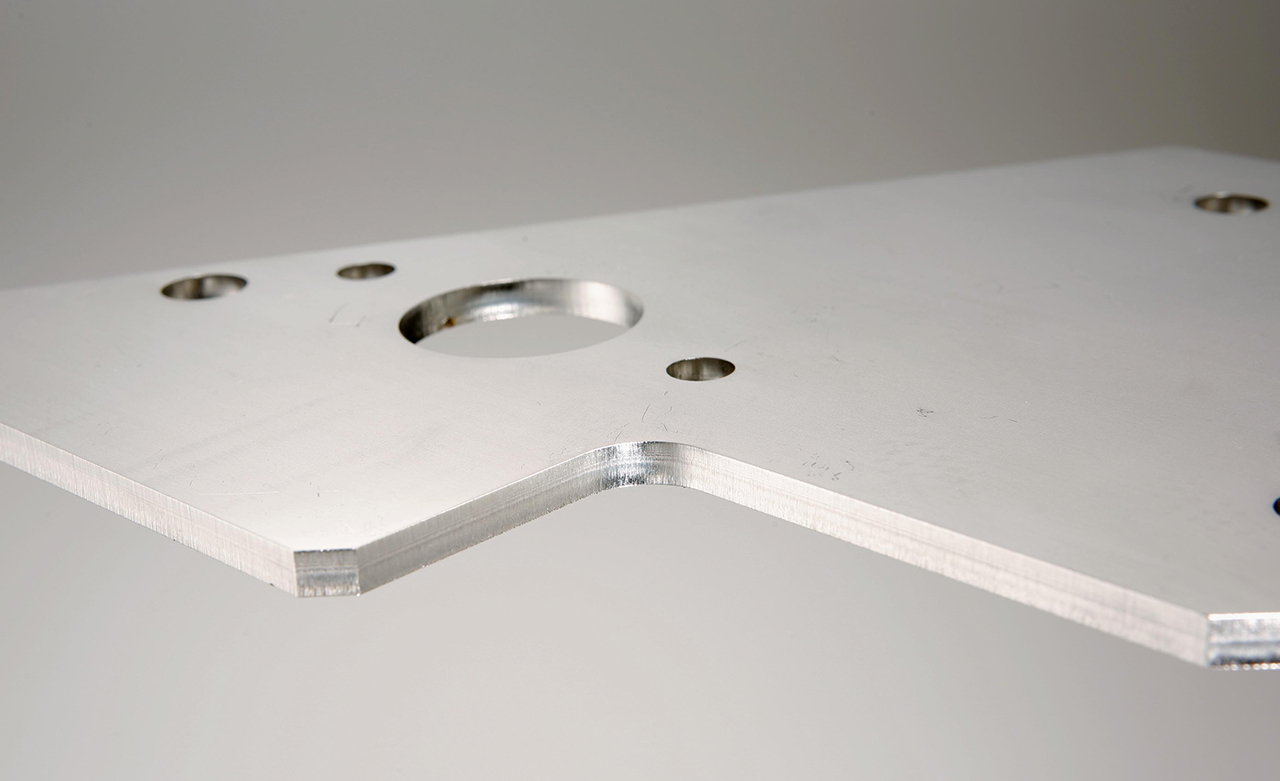

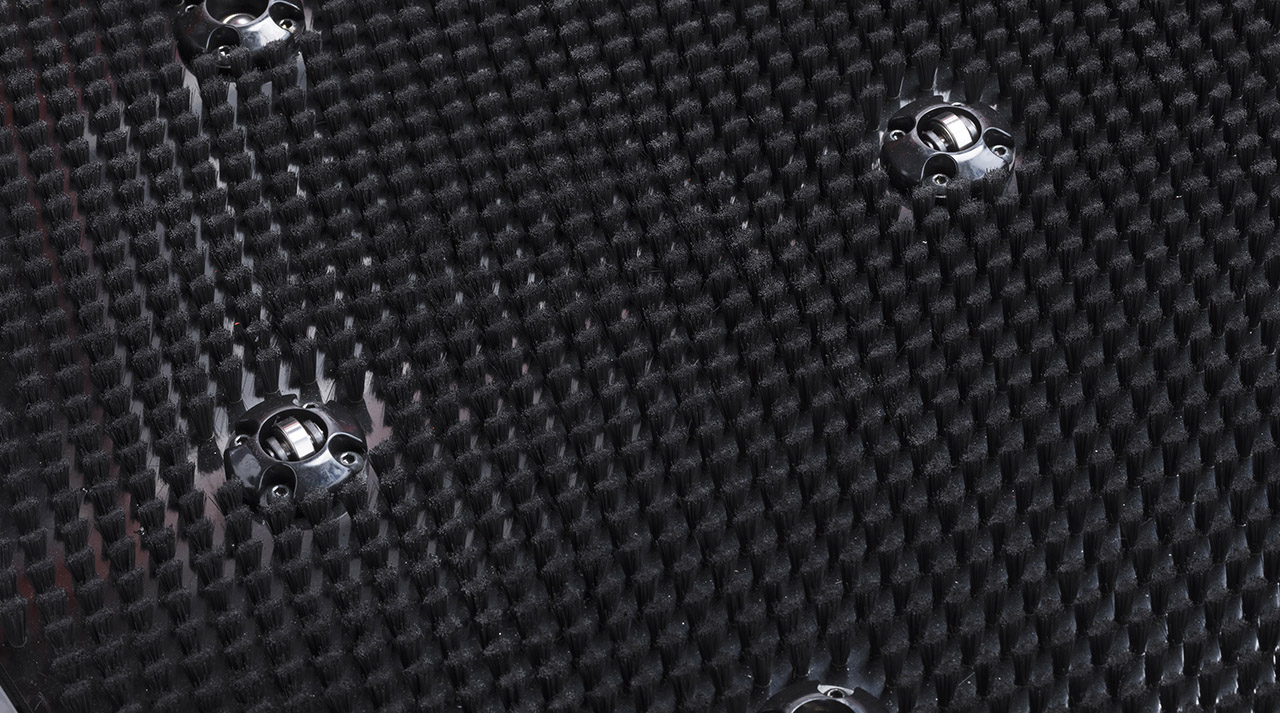

HIGH-DENSITY BRUSH TABLE:

To eliminate scratches on the underside of the material, the LC- ALPHA is equipped with a high-density brush table.

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.

Laser class 1 when operated in accordance to EN 60825-1